Business Process re-engineering is a business management strategy, originally pioneered in early 1990s, focusing on the analysis & design of workflows & business processes in an organization. Today organizations are managed today by a set of principles that have evolved since the beginning of the industrial revolution. This revolution started with the concept of division of labor, conceived by Adam Smith in 1776. According to this concept instead of one craftsman making an entire product (such as a shoe or a pin), several people would make the product each specializing in one task. Each task would be relatively simple, so it would be easy to learn. This would reduce the long apprenticeship periods. In addition, when people specialize in these simple tasks, output can increase. This situation led to cheaper products and higher demand. Since the tasks were simple, they were easy to automate when machines were introduced. Business Process re-engineering (BPR) is the process of rethinking & redesigning the way, work is done to better support an organizations missions, strategic goals, & customer needs.

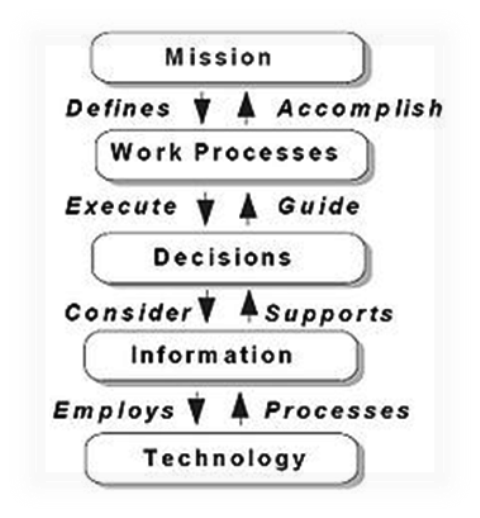

Within the framework of these assessment of mission & goals, reengineering focuses on the organization’s business process & Automation of the services provided by the company. Automation reduced the price of products further and further, and factories became larger and larger. Instead of producing for customers after an order was placed, products were produced in large quantities and sold in the market place. Several principles and methods were created over the years that enhanced the development of the Industrial Revolution.

The important aim of the BPR is

- Specialization of labor

- Mass production (producing large quantities, storing them, selling them at a later time)

- Hierarchical organizational structure following functional specialties with top down lines of authority

- Assembly lines that bring the work to the worker whenever possible

- Complex support systems for planning and budgeting, resource allocation, coordination, and control

These principles and methods were successful in developing world-class organizations, moving nations to a developed status, and significantly increasing standards of living. As long as the pace of the changes was slow, it was possible to deal with the changes by using continuous improvement programs, which included automation of existing processes, small structural modifications, quality and productivity improvement programs, and modifications in management procedures. However, as the pace and the magnitude of business pressures and changes accelerate, continuous improvement programs could become ineffective in many cases. As the saying goes, the old tricks simply do not work.

-NIKHIL JAIN

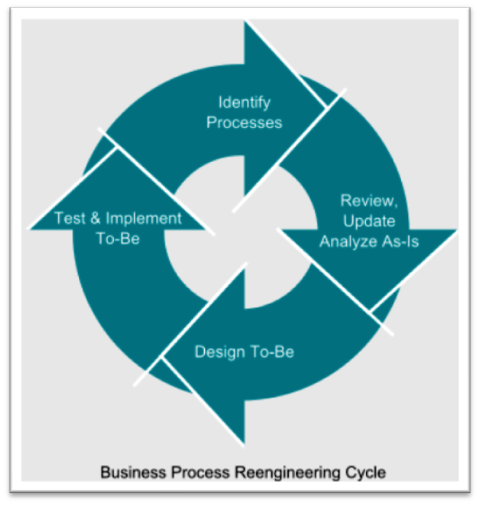

the process explained is very easy to understand because of pictorial representation